The Robotic Manufacturing Hurdle: Why Nike Sneakers Are Still Made By Humans

Table of Contents

The Complexity of Dexterous Manipulation

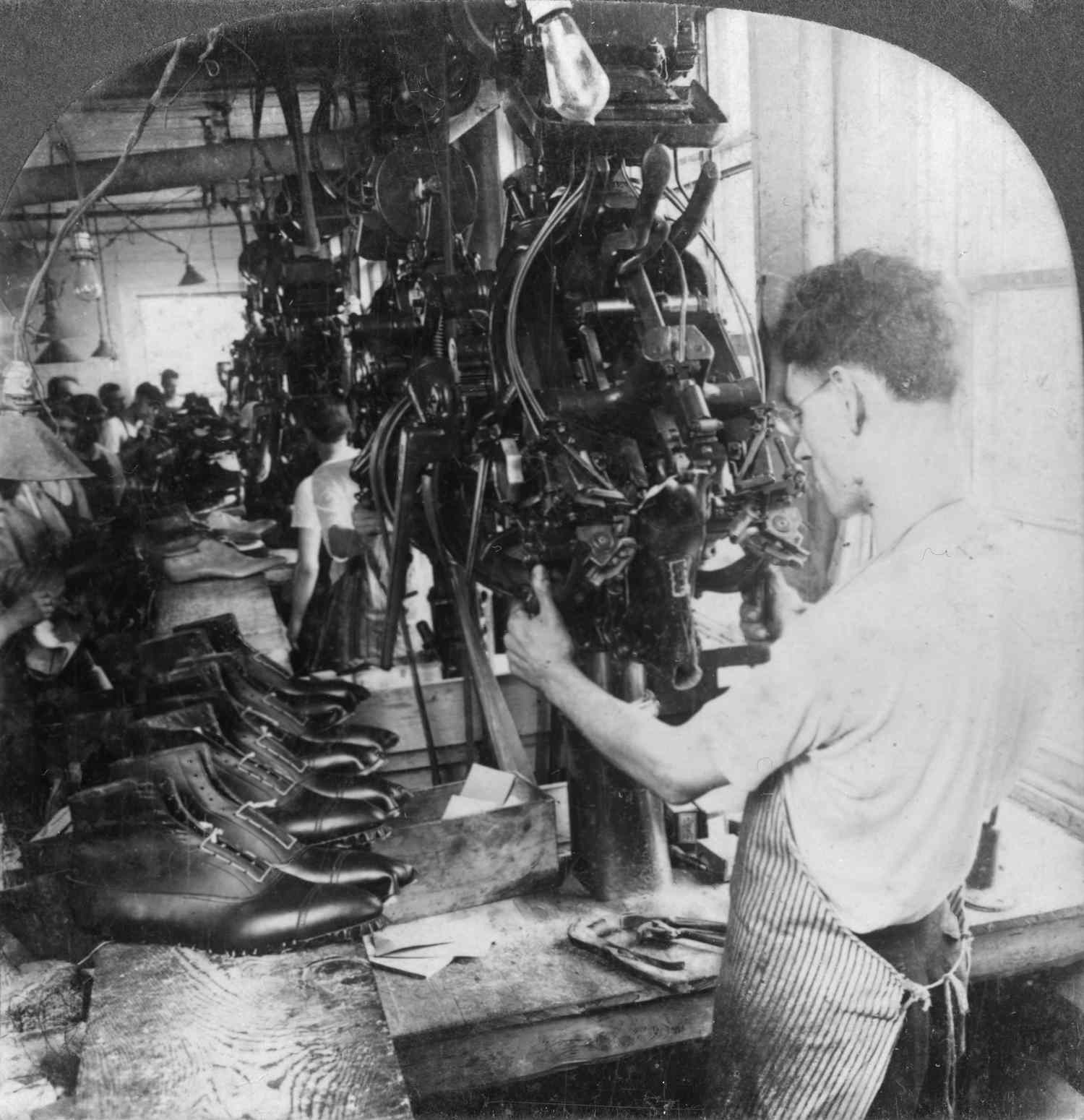

Assembling a Nike sneaker is far more intricate than it might seem. It's a delicate ballet of precise movements requiring a level of dexterity that current robots struggle to match. Consider the tasks involved:

- Precise stitching and gluing: The consistent application of glue and the precise stitching of various materials require fine motor skills and adaptability that robots currently lack. Inconsistent pressure or placement can lead to compromised quality and durability.

- Handling various materials (leather, fabric, rubber): Sneakers utilize a diverse range of materials, each with unique properties. Robots need advanced sensory capabilities to handle these materials without damaging them. The flexibility and softness of some fabrics, for instance, pose a significant challenge.

- Quality control requiring visual inspection and tactile feedback: Human inspectors can quickly identify subtle defects, inconsistencies in stitching, or material flaws through visual inspection and tactile feedback. Replicating this level of nuanced quality control with robots is a significant technological hurdle.

- Adapting to different shoe designs and sizes: Nike releases countless styles and sizes each year. Reprogramming robots to handle every variation is time-consuming and expensive, making mass customization challenging with current robotic technology.

This intricate process highlights the limitations of current robotic technology in replicating human dexterity and adaptability. Achieving true "dexterous manipulation" remains a key challenge in robotic manufacturing for the footwear industry.

Cost-Effectiveness and Return on Investment

Implementing advanced robotics in sneaker manufacturing requires a substantial upfront investment. The cost of purchasing, installing, and maintaining sophisticated robotic systems is high, often outweighing the cost of human labor, at least in the short term. Let's examine the financial aspects:

- High upfront costs of robots and specialized equipment: The initial investment in robotic arms, vision systems, and other specialized equipment can be enormous, particularly for complex tasks like stitching and gluing.

- Ongoing maintenance and repair expenses: Robots require regular maintenance and repairs, adding significant ongoing costs. Downtime due to malfunctions can also disrupt production and further increase costs.

- The need for skilled programmers and technicians: Operating and maintaining advanced robotic systems requires specialized expertise. The need for skilled programmers and technicians adds to the overall expense.

- Potential for lower productivity during initial implementation: The initial setup and programming phase of robotic systems can lead to lower productivity compared to experienced human workers. This needs to be factored into the ROI calculation.

Therefore, the return on investment (ROI) for automating certain sneaker production tasks is often questionable, especially when compared to the relatively lower cost and established efficiency of skilled human labor.

The Human Element in Quality Control and Innovation

Beyond the dexterity issue, the human element plays a crucial role in maintaining quality and driving innovation. Human workers bring an irreplaceable level of skill and intuition to the manufacturing process:

- Experienced workers' ability to identify inconsistencies and quality issues: A skilled worker can quickly spot even minuscule defects that might escape automated detection systems. Their experience allows them to judge subtle variations in material quality and stitching.

- Human adaptability in handling unexpected situations on the production line: Human workers can react flexibly to unforeseen problems, quickly adapting to changes and resolving issues with creative problem-solving. Robots, in contrast, typically require reprogramming for even minor deviations.

- The role of human input in design iterations and product development: Human designers and engineers constantly refine sneaker designs and manufacturing processes based on feedback and experience. This human-centric approach to innovation is invaluable.

- The importance of skilled craftsmanship in premium sneaker manufacturing: For high-end sneakers, the value of skilled craftsmanship is paramount. The precision and artistry of hand-stitching or hand-finishing add significant value to the final product.

Ethical Considerations and Job Displacement

The increasing automation of manufacturing inevitably raises ethical concerns about potential job displacement. The shift towards robotic manufacturing in the footwear industry could lead to significant job losses, particularly for those performing repetitive tasks. Addressing this societal impact through retraining programs and exploring alternative employment opportunities is crucial.

Conclusion

The "robotic manufacturing hurdle" in sneaker production remains a significant challenge. While robotic systems are increasingly integrated into some aspects of the manufacturing process, the complexity of dexterous manipulation, the high cost of implementation, and the irreplaceable human element in quality control and innovation continue to limit the extent of automation. While robotics play a growing role, fully automated sneaker production is still some way off. Further research and development are needed, particularly in areas like advanced dexterous manipulation and AI-powered quality control systems, to overcome this hurdle and improve efficiency while also carefully considering the ethical implications. We need to explore the future of robotic manufacturing in conjunction with human expertise for optimal sneaker production—a synergistic approach that balances technological advancement with human ingenuity.

Featured Posts

-

The Future Of Nordic Defense Exploring The Combined Capabilities Of Sweden And Finland

Apr 22, 2025

The Future Of Nordic Defense Exploring The Combined Capabilities Of Sweden And Finland

Apr 22, 2025 -

Fsus Post Shooting Plan A Controversial Return To Campus

Apr 22, 2025

Fsus Post Shooting Plan A Controversial Return To Campus

Apr 22, 2025 -

Death Of Pope Francis At 88 A Legacy Remembered

Apr 22, 2025

Death Of Pope Francis At 88 A Legacy Remembered

Apr 22, 2025 -

Robots Vs Sneakers The Complexities Of Automated Shoe Production

Apr 22, 2025

Robots Vs Sneakers The Complexities Of Automated Shoe Production

Apr 22, 2025 -

Razer Blade 16 2025 High End Performance In A Slim Package A Comprehensive Review

Apr 22, 2025

Razer Blade 16 2025 High End Performance In A Slim Package A Comprehensive Review

Apr 22, 2025