Robots Vs. Sneakers: The Complexities Of Automated Shoe Production

Table of Contents

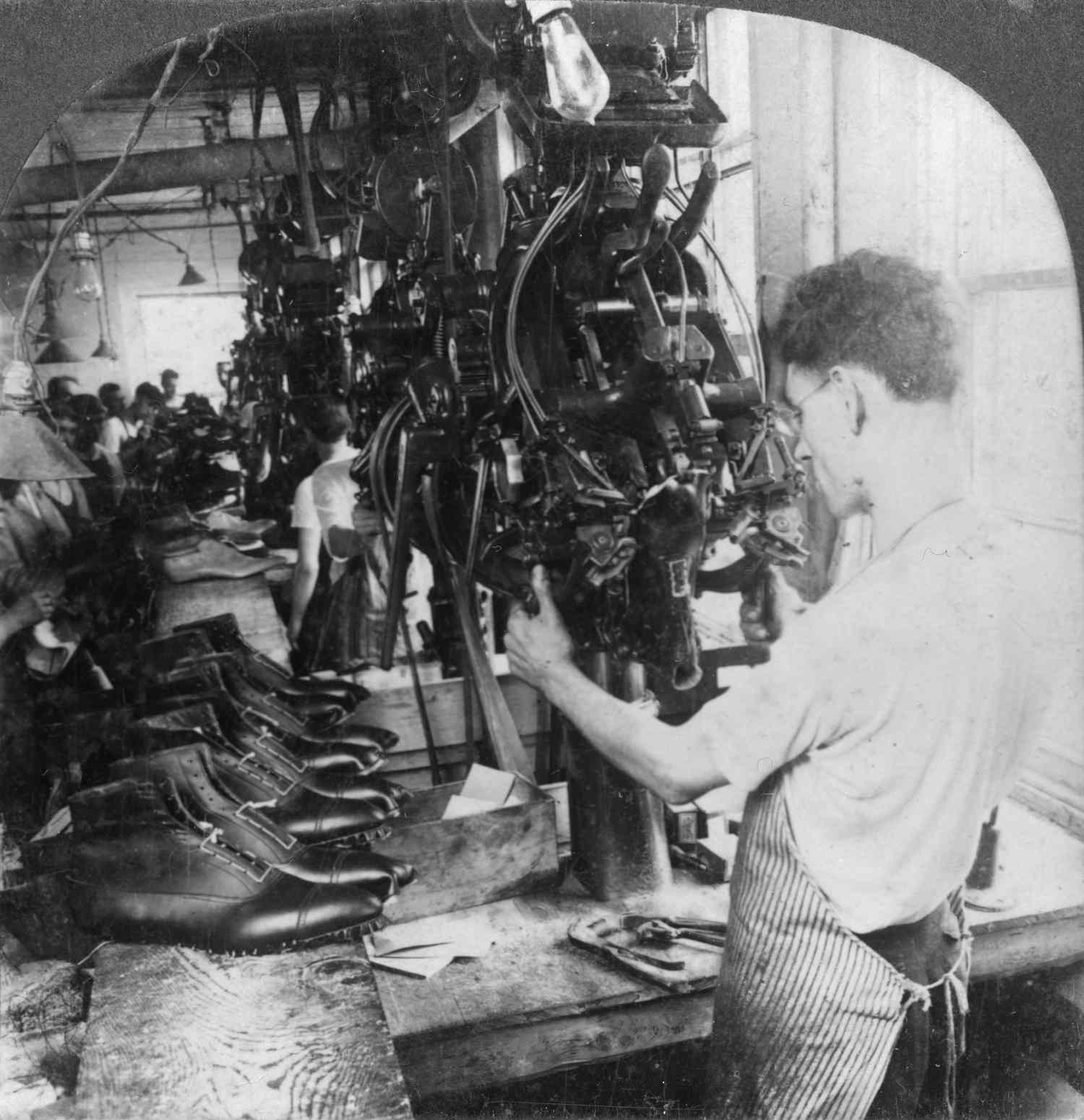

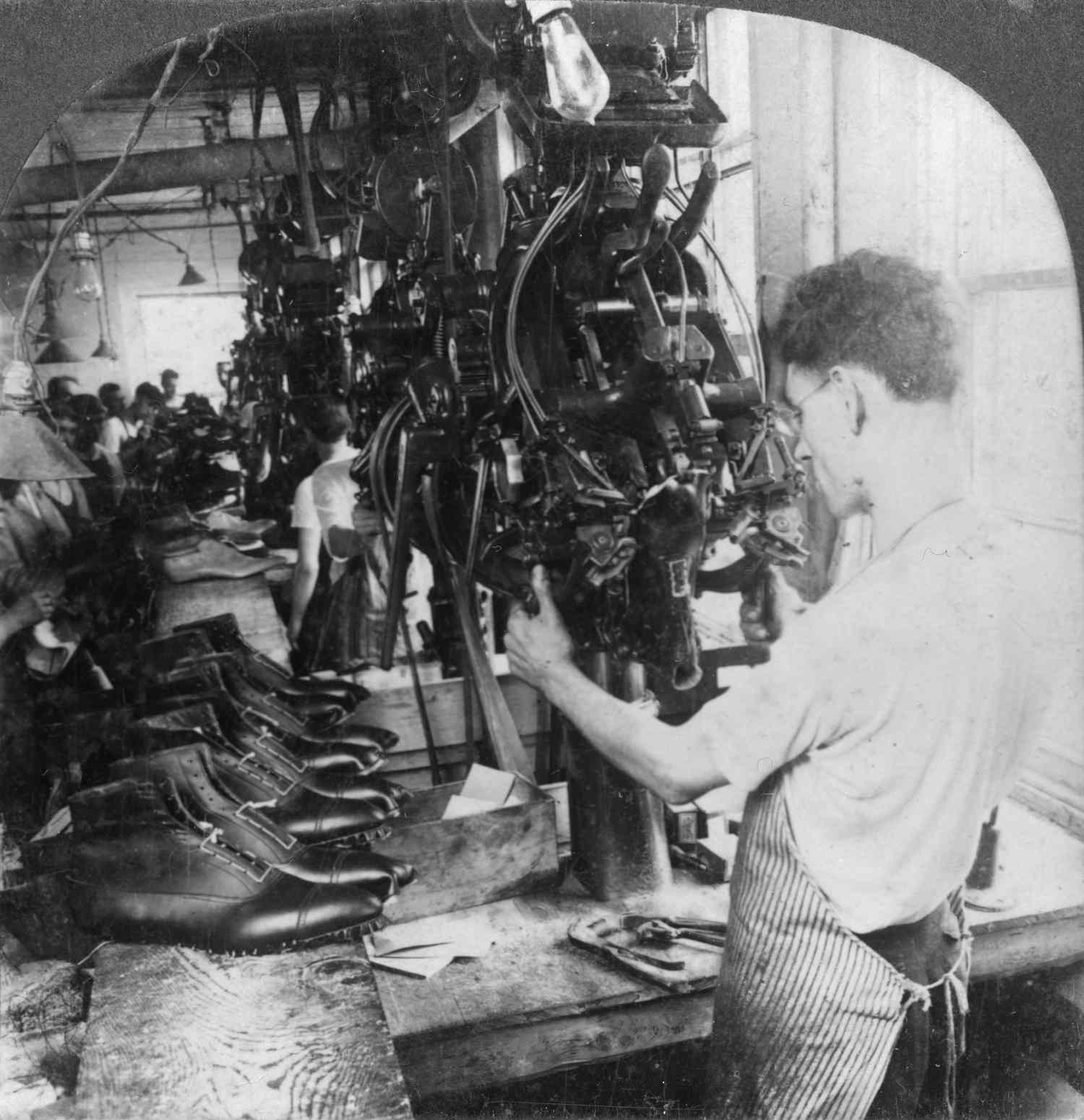

The Rise of Robotic Automation in Sneaker Manufacturing

The adoption of robots in sneaker factories is rapidly accelerating. Automation is no longer a futuristic concept; it's becoming integral to modern footwear production. Robots are being deployed across various stages, from the initial cutting of materials to the final assembly and packaging.

This increased automation offers several key advantages:

- Increased precision and accuracy in cutting and stitching: Robotic systems boast superior precision compared to manual labor, minimizing errors and resulting in cleaner cuts and more accurate stitching. This reduces material waste and improves the overall quality of the finished product.

- Reduced material waste through optimized cutting patterns: Advanced software integrated with robotic cutters can create optimized cutting patterns, minimizing material waste and contributing to more sustainable manufacturing practices. This is crucial in an industry grappling with the environmental impact of production.

- Faster production cycles leading to quicker market response times: Automated systems can operate continuously at higher speeds than human workers, significantly accelerating production cycles. This allows brands to respond more quickly to changing trends and consumer demands.

- Improved consistency in product quality: Robots perform repetitive tasks with unwavering consistency, leading to a more uniform product quality across large production runs. This eliminates variations that might occur with manual labor. This consistency is essential for maintaining brand reputation and meeting strict quality standards.

Specific examples of robotic systems include automated cutting machines using laser or knife technology, robotic arms performing stitching and assembly tasks, and automated quality inspection systems using computer vision.

Cost Analysis: Automation vs. Traditional Methods

Implementing robotic automation in sneaker manufacturing requires a significant upfront investment. The cost of purchasing and installing robotic systems, alongside the necessary infrastructure and software, can be substantial. This high initial capital expenditure is a major barrier to entry for smaller companies.

However, the long-term cost benefits of automation can be considerable. While the initial investment is high, the ongoing costs associated with traditional labor—including wages, benefits, and potential labor disputes—are significantly reduced.

Let's break down the cost comparison:

- High upfront capital expenditure for robotic systems: This is the biggest hurdle for many businesses considering automation. The cost varies greatly depending on the complexity of the system and the scale of the operation.

- Lower long-term labor costs through automation: Over time, the reduced need for manual labor translates into significant savings on wages, benefits, and associated expenses.

- Potential for increased efficiency and reduced operational expenses: Automation can lead to higher overall efficiency, reducing waste and optimizing resource utilization. This translates to lower operational expenses in the long run.

- Need for skilled technicians to maintain and repair robotic equipment: This is an ongoing cost. Companies need to invest in skilled technicians to maintain and repair the robotic systems, ensuring minimal downtime.

The return on investment (ROI) for automated shoe production depends on various factors, including the scale of operation, the specific robotic systems employed, and the overall market conditions. A thorough cost-benefit analysis is crucial before making such an investment. The impact on labor markets is also a key consideration, necessitating strategies for workforce retraining and upskilling.

Quality Control and Consistency in Automated Sneaker Production

One of the most significant advantages of robotic automation in sneaker production is the improvement in quality control and consistency. Robots perform tasks with far greater precision and repeatability than human workers. This translates into:

- Improved precision leading to fewer defects: The accuracy of robotic systems reduces the likelihood of errors during cutting, stitching, and assembly, resulting in fewer defects in the finished product.

- Consistent quality across larger production runs: Automation ensures that each sneaker produced meets the same high-quality standards, eliminating the variations that can occur with manual production.

- Reduced human error in assembly and finishing processes: Automation minimizes the potential for human error, leading to a higher overall yield of perfectly finished sneakers.

- Need for sophisticated quality control mechanisms to monitor robotic performance: While robots improve quality, it's crucial to have robust quality control systems in place to monitor the performance of the robotic systems and ensure they are operating optimally. This often involves automated vision systems and data analytics.

The Human Element: The Role of Skilled Workers in Automated Factories

While automation is transforming sneaker manufacturing, the human element remains crucial. The shift towards automation doesn't eliminate the need for human workers; rather, it transforms their roles.

- Shift from manual labor to specialized technical roles: Instead of performing repetitive manual tasks, human workers are increasingly needed for specialized roles such as programming, maintaining, and repairing robotic systems.

- Increased demand for robotics engineers and technicians: The growing adoption of robotics in the industry creates a higher demand for skilled technicians and engineers capable of installing, maintaining, and troubleshooting robotic systems.

- Importance of training and development programs for workers: Upskilling and retraining programs are essential to equip existing workers with the necessary skills to transition into these new roles. This requires investment from both companies and governments.

- Collaboration between humans and robots in the production process: The most effective approach involves a collaborative model where humans and robots work together, leveraging the strengths of both. Humans handle tasks requiring dexterity, problem-solving, and creativity, while robots handle repetitive, high-precision tasks.

The Future of Robots and Sneakers: Trends and Predictions

The future of robots and sneakers is bright, filled with exciting possibilities. Emerging technologies like AI and machine learning are poised to further revolutionize the industry:

- Increased use of AI for optimizing production processes: AI algorithms can analyze vast amounts of data to identify areas for improvement in efficiency, resource utilization, and quality control.

- Potential for mass customization of sneakers: Automation opens up the possibility of mass customization, where consumers can design and order personalized sneakers with specific features and designs.

- Growing demand for sustainable and ethical manufacturing practices in automated factories: Automation can contribute to more sustainable manufacturing by reducing waste and optimizing resource utilization. This is becoming increasingly important for consumers and brands.

- Ongoing innovation in robotic systems for improved efficiency and flexibility: We can expect continuous innovation in robotic systems, leading to even greater efficiency, flexibility, and adaptability in the production process.

Conclusion:

The integration of robots into sneaker manufacturing presents both significant opportunities and challenges. While automation promises increased efficiency, cost savings, and consistent quality, it also necessitates substantial upfront investment, skilled workforce adaptation, and careful consideration of ethical and economic implications. The future of sneaker production likely lies in a collaborative approach, leveraging the strengths of both robotic automation and human expertise to create high-quality, innovative footwear in a sustainable and responsible manner. To stay informed about the latest developments in this rapidly evolving field, continue exploring the complex relationship between robots and sneakers, including the impact of AI on sneaker production and the future of automated footwear manufacturing.

Featured Posts

-

Building Voice Assistants Made Easy Open Ais Latest Announcement

Apr 22, 2025

Building Voice Assistants Made Easy Open Ais Latest Announcement

Apr 22, 2025 -

Kyiv Under Pressure Responding To Trumps Plan To End The Ukraine Conflict

Apr 22, 2025

Kyiv Under Pressure Responding To Trumps Plan To End The Ukraine Conflict

Apr 22, 2025 -

Trump Presidency The Nationwide Protests And Their Impact

Apr 22, 2025

Trump Presidency The Nationwide Protests And Their Impact

Apr 22, 2025 -

Trumps Trade Policies A Threat To Us Financial Leadership

Apr 22, 2025

Trumps Trade Policies A Threat To Us Financial Leadership

Apr 22, 2025 -

Car Dealerships Step Up Resistance To Electric Vehicle Regulations

Apr 22, 2025

Car Dealerships Step Up Resistance To Electric Vehicle Regulations

Apr 22, 2025