Geopolitical Risks And Supply Chain Issues: Tesla's Optimus Robot Development Under Pressure

Table of Contents

Geopolitical Instability and its Impact on Optimus Robot Development

International tensions, trade wars, and sanctions create a volatile environment for any large-scale manufacturing project, and the Optimus robot is no exception. These geopolitical risks significantly impact the sourcing of critical components, potentially delaying production and increasing costs.

Raw Material Sourcing Challenges

The production of advanced robots like Optimus requires a complex array of raw materials. This includes rare earth minerals vital for powerful magnets in motors, lithium for batteries, and various metals for structural components.

- Rare Earth Mineral Dependence: China's dominance in rare earth mineral mining and processing poses a significant risk. Geopolitical tensions with China could disrupt the supply of these crucial materials, leading to production delays or price hikes.

- Lithium Supply Chain Vulnerabilities: Lithium, essential for the robot's battery, is primarily sourced from countries with varying levels of political stability. Disruptions in these regions can directly impact Optimus's production timelines.

- Ethical Sourcing Concerns: Growing pressure to ensure ethical and sustainable sourcing adds another layer of complexity. Companies must navigate regulations and consumer expectations regarding conflict minerals and environmentally responsible practices.

Manufacturing Location Risks

Choosing a manufacturing location for the Optimus robot involves careful consideration of geopolitical stability and potential risks.

- Political Instability: Manufacturing in regions prone to political unrest or civil conflict introduces risks of production shutdowns, damage to facilities, and disruptions to the workforce.

- Natural Disasters: Locations susceptible to earthquakes, floods, or other natural disasters can cause significant production delays and damage.

- Diversification Strategies: To mitigate these risks, Tesla might consider diversifying its manufacturing locations, spreading production across multiple regions to reduce dependence on any single location. This, however, comes with its own set of logistical challenges and increased costs.

Supply Chain Disruptions and their Effects on Optimus Robot Production

The intricate global supply chains required for high-tech manufacturing are notoriously vulnerable to disruptions. Even minor setbacks can have a cascading effect, delaying production and increasing costs.

Semiconductor Shortages and their Implications

Semiconductors are the brains of any robot, and the current global shortage presents a major challenge.

- Critical Role of Semiconductors: Optimus relies on numerous sophisticated semiconductors for its control systems, sensors, and computing capabilities.

- Production Delays: The semiconductor shortage could lead to significant delays in Optimus's production schedule, potentially pushing back the launch date indefinitely.

- Mitigation Strategies: Tesla might explore vertical integration (producing its own semiconductors) or forging strategic partnerships with semiconductor manufacturers to secure a stable supply.

Logistics and Transportation Bottlenecks

Port congestion, shipping delays, and logistical challenges further complicate the already intricate supply chains.

- Increased Costs: Supply chain disruptions lead to increased transportation costs, impacting the overall profitability of the Optimus project.

- Delivery Delays: Delays in the delivery of even minor components can halt the entire production process, leading to further delays and cost overruns.

- Supply Chain Resilience: Implementing strategies to improve supply chain resilience, such as diversifying shipping routes and using alternative transportation methods, can mitigate these risks.

Mitigation Strategies: How Tesla Can Address Geopolitical Risks and Supply Chain Issues

Tesla must proactively implement mitigation strategies to navigate these challenges and ensure the success of the Optimus robot project.

Diversification of Suppliers and Manufacturing Locations

Reducing reliance on single suppliers and spreading manufacturing across multiple regions is crucial for risk mitigation. This diversification strategy helps absorb shocks caused by disruptions in one specific area.

Investment in Supply Chain Technology

Leveraging AI and data analytics to improve supply chain visibility, predict potential disruptions, and optimize logistics can help Tesla anticipate and respond to challenges more effectively.

Building Strategic Partnerships

Collaboration with other companies in the supply chain can lead to shared risk and improved resilience. Strategic partnerships enable better resource allocation and knowledge sharing.

On-shoring and Near-shoring Strategies

Bringing manufacturing closer to home (on-shoring) or to nearby countries (near-shoring) can reduce transportation costs, improve lead times, and enhance control over the supply chain. However, this strategy must also weigh the potential increase in labor costs.

Conclusion: Navigating Geopolitical Risks and Supply Chain Issues for Optimus Robot Success

The development of Tesla's Optimus robot faces significant hurdles due to geopolitical risks and supply chain issues. From securing rare earth minerals to navigating semiconductor shortages and logistical bottlenecks, the challenges are numerous and interconnected. Proactive risk management, encompassing diversification strategies, technological investments, strategic partnerships, and a careful evaluation of on-shoring/near-shoring options, is crucial for the project's success. Understanding the complexities of geopolitical risks and supply chain issues is crucial for assessing the future of innovative projects like Tesla's Optimus robot. Stay informed about these challenges to better anticipate the future of robotics and automation.

Featured Posts

-

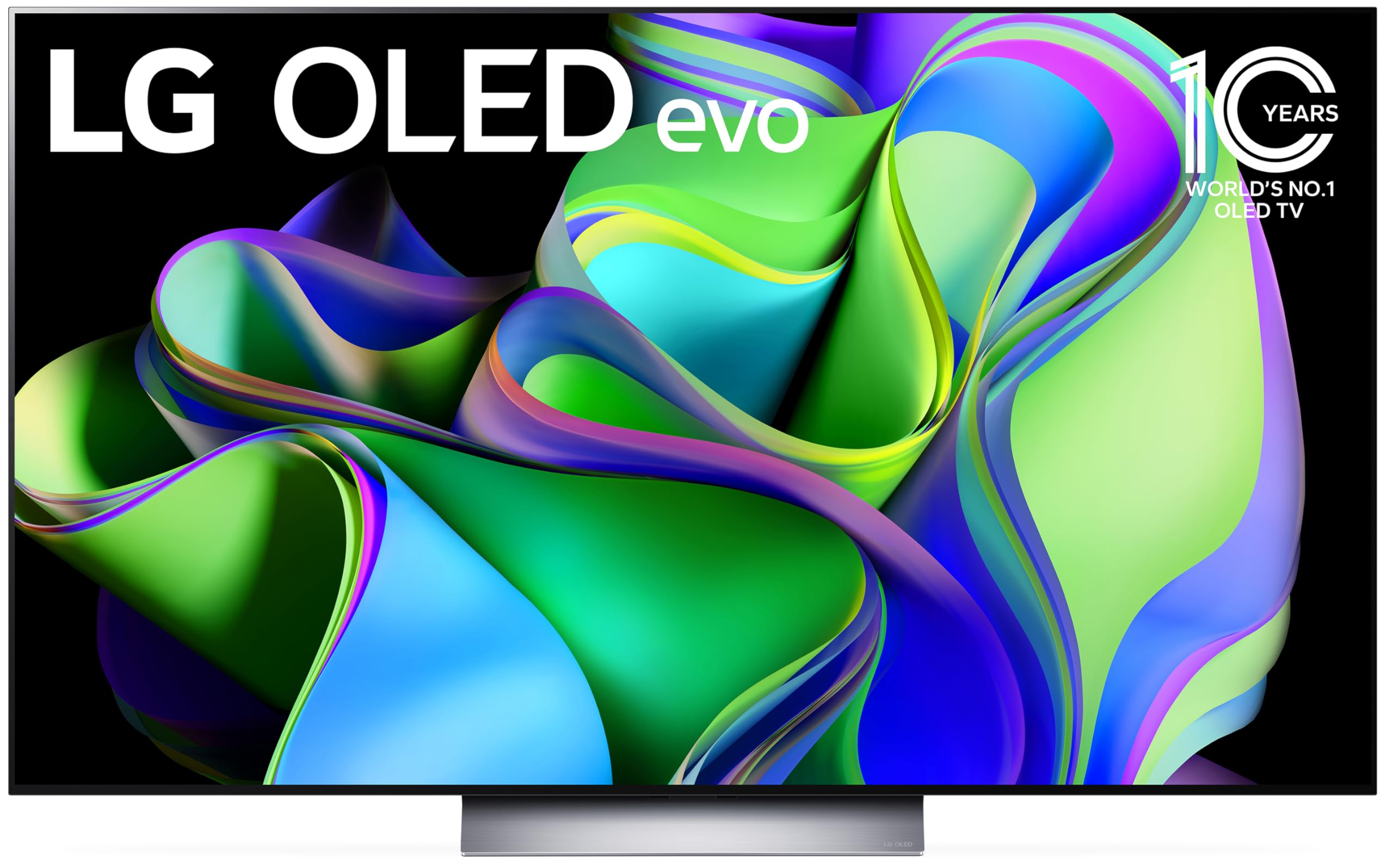

My 77 Inch Lg C3 Oled Tv A Detailed Review

Apr 24, 2025

My 77 Inch Lg C3 Oled Tv A Detailed Review

Apr 24, 2025 -

John Travolta Reassures Fans Following Controversial Family Home Photo

Apr 24, 2025

John Travolta Reassures Fans Following Controversial Family Home Photo

Apr 24, 2025 -

Credit Card Industry Faces Headwinds Amidst Reduced Consumer Spending

Apr 24, 2025

Credit Card Industry Faces Headwinds Amidst Reduced Consumer Spending

Apr 24, 2025 -

Unconventional Approach How A Startup Airline Leverages Deportation Flights

Apr 24, 2025

Unconventional Approach How A Startup Airline Leverages Deportation Flights

Apr 24, 2025 -

Remembering Sophie Nyweide Child Star Of Mammoth And Noah Dies At 24

Apr 24, 2025

Remembering Sophie Nyweide Child Star Of Mammoth And Noah Dies At 24

Apr 24, 2025